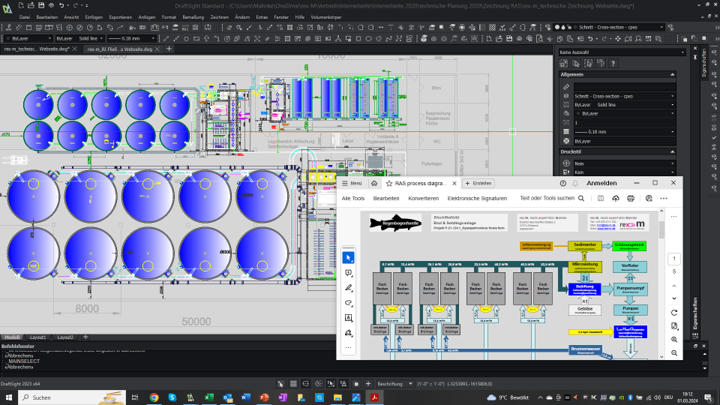

As part of the technical planning of RAS, I develop system descriptions, process diagrams, detailed technical drawings and extensive tabular overviews.

An aquaculture system is made up of the habitat, water recirculation and water treatment. The process technology consists of machines, tanks, basin installations, pipelines and biofilter material. The calculation particularly is based in fish feed amount and water recirculation.

My specification includes manufacturers, prices, dimensions, connections, capacity, performance, hydraulics and consumption. In summary I show the capital expenditure and the operating costs.

Fish tanks

Hatchery tanks are drained using a telescopic outlet. With separation grids raceways are divided into sections.

For large circular tanks I use the “Cornell Dual Drain” design. The main part of the runoff is routed via the side wall drain.

Water treatment

Microscreen drum filters remove suspended solids. Fine suspended solids will be controlled in submerged fixed bed bio reactors (FBBR).

I use self-cleaning moving bed bio reactors (MBBR) as biofilter. Ozone is used in RAS with denitrification. Otherwise, germs will be reduced by UV-light.

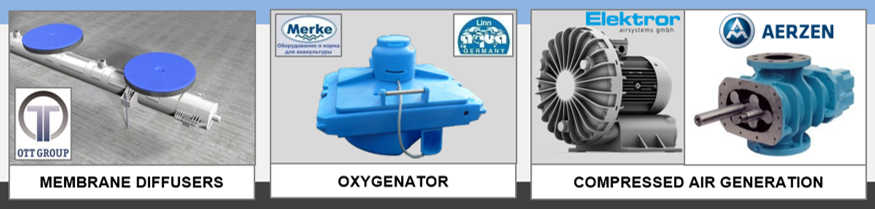

Low-head or pressure-free, mechanical oxygenators enrich oxygen. Emergency-oxygenation starts in case of dysfunctions.

PH will be adjusted by dosing of lime or soda.

Water recirculation

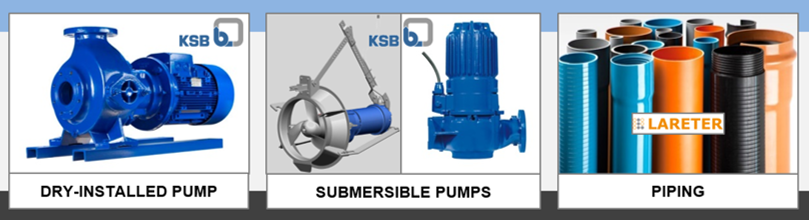

My large-scale RAS are characterized by low-head design and propeller pumps. Submersible and dry positioned pumps are utilized in small-scale aquaculture systems and for bypass-filter.

PVC pressure pipes are suitable up to nominal size DN250. PVC sewage pipes are available up to DN500. For larger nominal diameters I plan PE-pipes.