Based on my decades of practical experience, my fish farm design is characterized by species-specific dimensioning and practice-oriented management. The capacity of the fish farm is based on the parameters product, stocking and species-specific indicators. Either give me the production capacity or it will be limited by location factors like need for space and water availability.

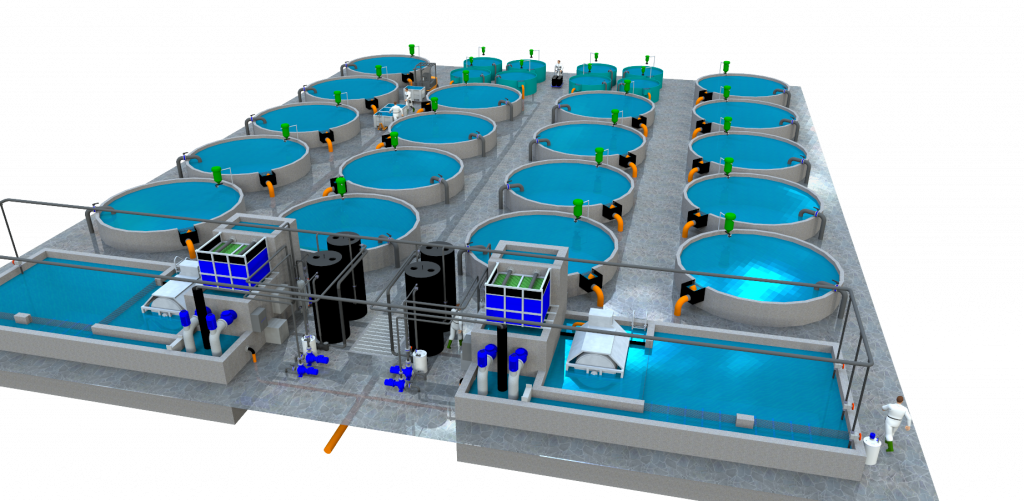

The water availability is of vital importance for the selection of the process technology. Aquaculture systems equipped with mechanical filters, aeration systems and recirculation pumps are flow-through systems with recirculation. While a targeted oxygen supply and an adequate water flow can be realized, ammonia is decisive for the water demand.

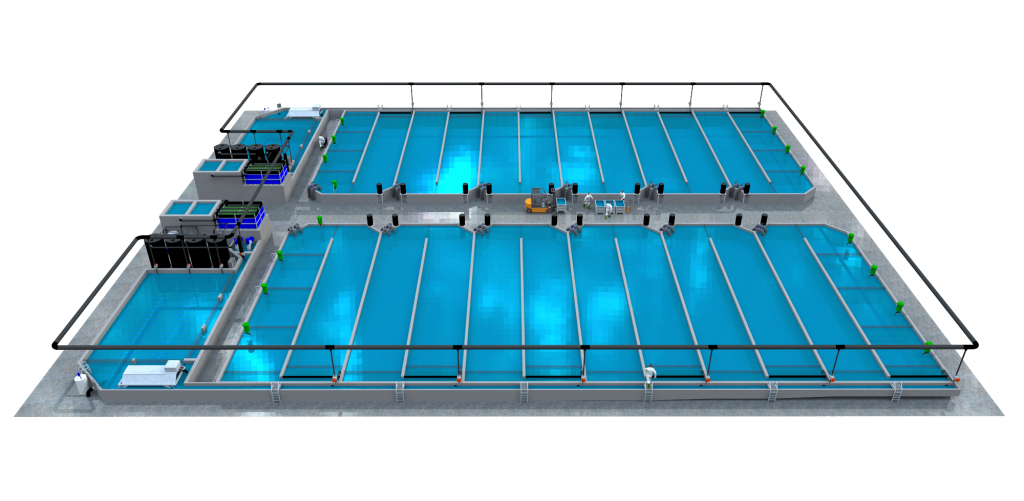

Recirculating aquaculture systems integrate biofilters into the water treatment. As a result fish production is limited by nitrate. Therefore RAS with denitrification require particularly little exchange water. I reject further water saving to avoid treating and reusing backwash water.

From an economic point of view at many locations it can make sense to avoid buildings and HVAC systems. Then due to seasonality I have to consider different growth curves for each batch of fish.

Due to high dilution the runoff water from flow-through systems is moderately polluted. If possible, I use a dual drain strategy in order to drain the concentrated sediment separately from the clear water overflow. In any case solids must be removed mechanically and stored prior to discharge.

The sewage from RAS is more polluted and must be treated not only mechanically but also biologically and, if necessary, chemically before being discharged. If there is sufficient space, the costly phosphate precipitation can be replaced by nutrient retention in fining ponds.